Thermablok® Technical Support

Thermablok® Technical Support

Thermablok Physical Properties

| Thickness | 0.4 in (10 mm) TYP |

| Max. Use Temperature | 400°F (200°C) |

| Color | Grey or White |

| Density | 9.4 lb/ft3 (0.15 g/cc) |

| Hydrophobic | Yes |

| Material Form | 57 in (1,450 mm) wide 3/8″ X 1.5″ X 4.5′ long |

| R-Value | R-Value = 10.3 / inch |

Thermablok Standards Organization Test Results

| Test Procedure | Property | Results |

|---|---|---|

| ASTM C 177 | Thermal Conductivity via Guarded Hot Plate | 0.0131 W/m*K @ 10°C |

| EN 12667 | Thermal Conductivity via Guarded Hot Plate | 0.0131 W/m*K @ 10°C |

| ASTM C 518 | Thermal Conductivity via Heat Flow Meter | 0.0148 W/m*K @ 2°C (avg of 3 samples) |

| ASTM E 84 | Flame and Smoke Spread | Class A: FSI >5, SDI 20 |

| EN13501-1: 2007 | Reaction to Fire Performance | Passed Euroclass C-s1,d0 |

| ASTM C 165 | Compressive Stress / Strain | 8.0psi @ 10% strain, 30.5 psi @ 25% strain |

| Specific Heat | Specific Heat | 1.00 J/g*K @ 40°C |

| ASTM E 96 | Water Vapor Transmission Rate | 1877 ng/Pa*s*m2 (dry cup method) |

| ASTM E 228 | Linear Coefficient of Thermal Expansion (@ 10°C) | X: 1.06 x 10-5 K-1, y: 1.90 x 10-5K-1 |

| ASTM C 1104 | Water Vapor Sorption | Mass Gain = 1.08% |

Common Insulators: R-Value/U-Value – Energy of Mfg/CO2 (Environmental Impact)

| Material | R-Value | U-Value* (W/m-K) | Energy/Mfg | CO2/Mfg | Health & Safety | Environment |

|---|---|---|---|---|---|---|

| Thermablok | 10.3 USA 1.813 Metric | 0.014 | 50.0 | 4.2 | No Known Hazards(Occupants/Environment) | 100% Recyclable(Air/Sand/Poly) |

| Fiberglass | 3.8 USA 0.669 Metric | 0.040 | 39.2 | 1.9 | Some Fiberglass Contains Formaldehyde – Toxic SbO3 | Recyclable |

| Polyisocyanurate | 6.0 USA 1.056 Metric | 0.024 | 69.8 | 5.5 | Creates Hydrogen Cyanide During a Building Fire | Thermoset – Plastic Not Recycled Petroleum Product |

| Polystyrene (Expanded) (Extruded) | Flame and Smoke Spread | 0.032 | 116.3 | 3.0 | Contains Mutagens – Suspected Carcinogens – Some add Toxic HBCD | Polluting the Oceans Little is Recycled (Breaks down in the Environment creating Vinyl-Benzene) Petroleum Product |

Notes: R-value is expressed in ft2•h•°F/Btu. U-value is expressed in W/m-K per standard convention.

- Thermal conductivity, k, is the property of a material that indicates its ability to conduct heat. It appears primarily in Fourier’s Law

for heat conduction. Thermal conductivity is measured in watts per kelvin per metre (W•K−1•m−1). Multiplied by a temperature

difference (in kelvins, K) and an area (in square metres, m2), and divided by a thickness (in metres, m) the thermal conductivity

predicts the power loss (in watts, W) through a piece of material.

- Thermal conductivity, k, is the property of a material that indicates its ability to conduct heat. It appears primarily in Fourier’s Law

- Wall assembly R-values are computed and expressed in the U.S. in (ft2•h•°F/Btu). Thermablok U -value expressed using this

measurement is 0.0971 (BTU-in/ft2•h•°F).

- Wall assembly R-values are computed and expressed in the U.S. in (ft2•h•°F/Btu). Thermablok U -value expressed using this

- Metric U-factors are defined as Watts per square meter per degree Celsius. To convert inch-pound Imperial U-values to metric U-factors,

multiply by 5.678. To convert metric U-factors to Imperial inch-pound U-factors, divide by 5.678.To convert Imperial inch-pound

R-values to metric R-values, multiply by 0.1761. One inch = 2.54 cms. One (RSI) U-factor coefficient = 5.678; one R-value = .1761 RSI.

- Metric U-factors are defined as Watts per square meter per degree Celsius. To convert inch-pound Imperial U-values to metric U-factors,

- USA R Value X 0.176 = Metric R Value

Wall R-Value Losses from Thermal Bridging

| Nominal Framing Depth & Spacing | “Labeled” Batt Insulation R-Values Between Studs | Effective R-Values Batt Installation / Steel Studs | Wall Thermal Loss R-Value |

|---|---|---|---|

| 2″ X4″ @ 16″ Center | R-11 R-13 R-15 | 5.5 6.0 6.4 | 50% 64% 67% |

| 2″ X 4″ @ 24″ Center | R-11 R-13 R-15 | 6.6 7.2 7.8 | 40% 45% 48% |

| 2″ X 6″ @ 16″ Center | R-19 R-21 | 7.1 7.4 | 63% 65% |

| 2″ X 6″ @ 24″ Center | R-19 R-21 | 8.6 9.0 | 55% 57% |

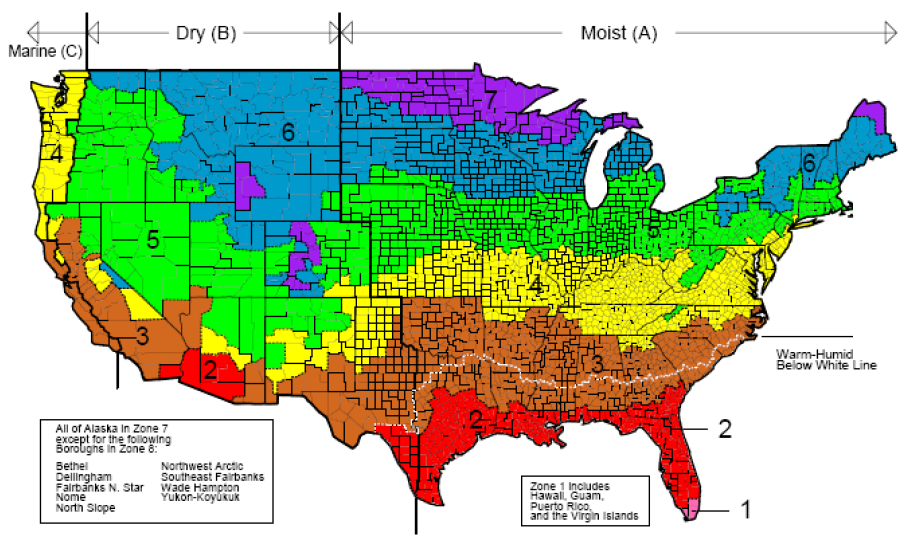

Meeting ASHRAE 90.1-2007 Building Envelope Requirements for U.S. Climate Zones

| Climate Zone | Nonresidential Requirements All occupancies other than residential | Residential Requirements Spaces in buildings used primarily for living and sleeping. Residential spaces include, but are not limited to, dwelling units, hotel/motel guest rooms, dormitories, nursing homes, patient rooms in hospitals, lodging houses, fraternity/sorority houses, hostels, prisons and fire stations. |

|---|---|---|

| 1 | R-13 + 0 ci U= 0.124 R= 10.6 | R-13 + 0 ci U= 0.124 R= 10.6 |

| 2 | R-13 + 0 ci U= 0.124 R= 8.06 | R-13 + 7.5 ci U= 0.064 R= 15.63 |

| 3 | R-13 + 3.8 ci U= 0.084 R= 11.90 | R-13 + 7.5 ci U= 0.064 R= 15.63 |

| 4 | R-13 + 7.5 ci U= 0.064 R= 15.63 | R-13 + 7.5 ci U= 0.064 R= 15.63 |

| 5 | R-13 + 7.5 ci U= 0.064 R= 15.63 | R-13 + 7.5 ci U= 0.064 R= 15.63 |

| 6 | R-13 + 7.5 ci U= 0.064 R= 15.63 | R-13 + 7.5 ci U= 0.064 R= 15.63 |

| 7 | R-13 + 7.5 ci U= 0.064 R= 15.63 | R-13 + 15.6 ci U= 0.042 R= 23.8 |

| 8 | R-13 + 7.5 ci U= 0.064 R= 15.63 | R-13 + 18.8 ci U= 0.037 R= 27.0 |

Basic Thermal Definitions

Thermal conductivity is an intensive property of a material that measures its capacity to sustain heat flow. The units of thermal conductivity are often provided in metric values of Watts/meter-degree Kelvin or W/m-K. The symbol used to denote thermal conductivity is k (or lambda, λ).

- There are many different unit conversions to Imperial and others:

- 1 BTU/ft hr F = 1.73 W/m-K or 1730 mW/m-K

- 12 BTU-in/ft2 hr F = 1 BTU/ft hr F = 1.73 W/m-K

- 1 BTU-in/ft2 hr F = 0.144 W/m-K or 144 mW/m-K

- The reciprocal of thermal conductivity is thermal resistivity; an intensive property of a material to resist one-dimensional heat flow.

Thermal resistivity has units of m-K/W.

- R is thermal resistance, which is the capacity of a material to impede heat flow over a given area and at a specific temperature.

The greater the value at a given set of conditions, the better the material will perform as a thermal insulator.

- R is thermal resistance, which is the capacity of a material to impede heat flow over a given area and at a specific temperature.

- The units of thermal resistance are provided in m2-K/W (or ft2 hr °F/BTU).

- Thickness/k value = R value.

- Resistances of insulators in series can be added.

- R-value can be for whole thickness or normalized (e.g. R-value is 12 per in or 24 for 2 inches of R-12 per inch material).

- R/in = 144/k (in mW/m-K) -> 12 mW/m-K = 12 per inch R value.

- The reciprocal of thermal resistance is thermal conductance (also known as the heat transfer coefficient), with units of W/m2 K.

This value is frequently measured in systems as the overall heat transfer coefficient (OHTC).

- The reciprocal of thermal resistance is thermal conductance (also known as the heat transfer coefficient), with units of W/m2 K.

- Thermal resistance values are often used in the building and construction markets as a relative measure of thermal insulation

performance for materials and systems.

Heat Transfer Coefficient (U Value)

- U values measure thermal conductance, a measure of a material or system to permit power flow per unit area and temperature change (W/m2 K).

U-value is heat transfer coefficient.

Low U values mean good insulation values (very similar to thermal conductivity k).

OHTC -> Overall heat transfer coefficient; frequently used to measure the thermal conductance of systems.

In the world of systems thermal engineering – U value and OHTC are often used synonymously.